Designing With Energy

The energy that goes into manufacturing our material world is the largest component of our energy consumption and something designers can impact directly. Yet few people understand this embodied energy, or actively design with it in mind.

"The real issue is not our direct consumption of energy but the greenhouse gases embodied in the goods we buy."

Monbiot (2010)

Understanding embodied energy

Our own understanding of embodied energy started with a very personal exploration. Having realised he knew next to nothing about the energy implications of all his belongings, Rich attempted to catalogue and calculate the embodied energy of everything he owned.

These calculations were very rough, but gave us an approximate figure for all his belongings, allowing us to compare different elements of his lifestyle. Computers and camera gear, with their exotic circuit board materials and batteries, far outweighed everything else, while some things like bike equipment turned out to be surprisingly insignificant. This showed us that you have to run the numbers, however crudely, and you will reveal all sorts of insights into the energy stories of our stuff.

Exploring the data

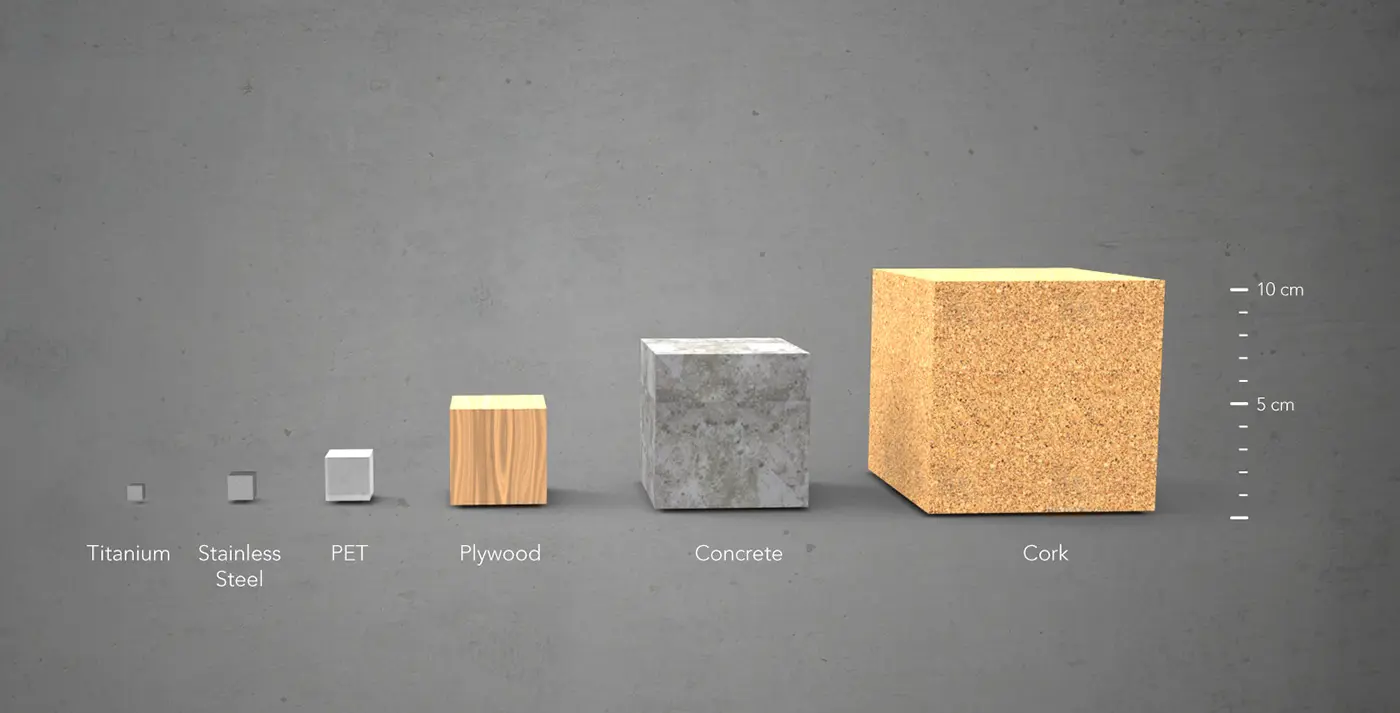

The data itself can be confusing, as you need to factor in material density to understand the implications for a given material. We found one of the best ways to look at the data was to show the volume of the material that can be produced for 1 megajoule of energy. This gives you a more tangible idea of the energy intensity of a material. The image below shows the volume of each material that could be manufactured with 1 megajoule of energy.

The video below shows one of our studio experiments applying this volume technique to more complex products, so you can ‘see’ a product’s embodied energy.

These approaches to visualising and analysing products using embodied energy data have given us a much richer understanding of the numbers. They allow anyone to quickly understand the impact of materials, and assess where there is the greatest potential for change.

New design approaches

Having gathered a lot of data, what we were really interested in was how this data would affect the design process. There were various tools for doing life cycle analysis on finished designs, but we wanted to experiment with ways of using embodied energy to drive the design process from the start. We set a simple design brief with ambitious energy quotas: to redesign the anglepoise lamp (which weighed in at 140 megajoules) to quotas of 1, 10, and 20 megajoules. The idea was to make energy the driving force behind the design process, and see what happened.

A 1-megajoule lamp

You really can't make that much of any material for 1 megajoule, which made this lamp somewhat challenging. Anything that used a subtractive process was ruled out straight away as this would throw away some of the tiny quota. We looked for a formable material that would give the largest volume per megajoule. This led, rather confusingly, to concrete. We were under the impression that concrete was an environmentally reprehensible material because it counted for around 7% of global emissions. In fact, it has one of the lowest embodied energy and carbon figures. The issue is not with the material itself, but that we use an awful lot of it (approximately three tonnes for every person on the planet each year). By casting the concrete, we could squeeze as much functionality out of 1 megajoule as possible, making a form that could sit in a few positions or be hung on its hook - not quite the functionality of the anglepoise, but not bad for a tiny fraction of the energy.

A 10-megajoule lamp

Designing a 10-megajoule lamp meant we suddenly had an abundance of material by comparison. In fact, we had enough hardwood to make a task lamp-sized structure. This started with a simple pivot design controlled with a nut and bolt. We quickly realised that the nut and bolt used up a megajoule and a half of the energy quota, which meant the lamp had to be considerably smaller. Instead, we focused on a metal-free adjustment mechanism and found a rather satisfying solution using the friction of cork to hold the lamp at different positions.

A 20-megajoule lamp

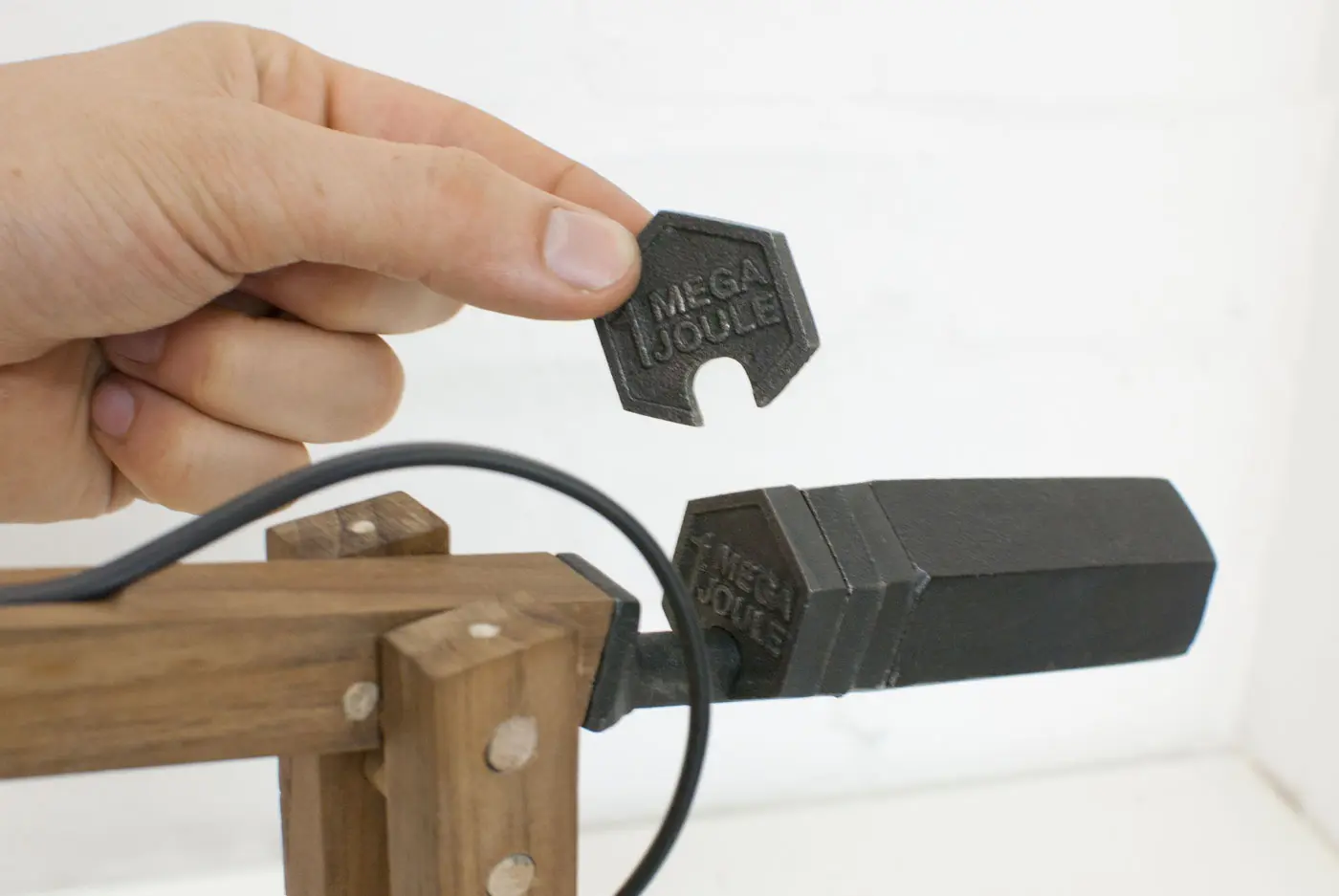

20 megajoules frankly seemed like an excessive amount of material after the first two lamps. We had enough quota to create a cast iron counter weight that allowed the lamp to balance at different heights. We decided to bring the idea of physical data into the product and cast the counterweights in 1-megajoule amounts, so the lamp could be adjusted by embodied energy.

Simple tools to make energy part of the creative process

It was clear to us that thinking about material selection and embodied energy at an early stage in the design process could have a huge impact. But we were also aware that very few designers were familiar with this data. To try and correct this, we wanted to take the data we had collated and put it into a format that better suited the design process. To do this we created Energy Trumps, which is a deck of cards that visualise the environmental properties of 45 selected materials. They present key environmental metrics in a fast and accessible way, enabling designers to make more informed material choices early in their process.

Through our Energy Trumps web app, users can explore the data in 3D, seeing the different volumes of material that can be produced with 1 megajoule of energy.

Our journey from discovering this data to fully integrating it into our design process has challenged and changed our perceptions about a range of materials and products. Ultimately, embodied energy has become a lens through which we assess design decisions and ensure our strategy is the right one. This ranges from looking for lightweighting and material substitution within a product, to rethinking how we deliver functionality.