ProjectBox

ProjectBox brings together everything you need to complete a DIY task in one carefully curated package: tools, consumables and instructions. It is helping Europe’s largest DIY retailer transition to a circular economy model by making hiring more desirable than buying.

DIY purchases are often very price-driven. Projects can require a lot of new tools, pushing consumers to the lower end of the market, where tools compete on price rather than quality. This can lead to a poor DIY experience. Once the project is completed, the tools are stored until they are needed again, which could be years in the future.

This isn’t a sustainable model in the long term. Can we move the DIY market away from this linear approach to the circular economy?

In principle the answer is simple: let's hire rather than buy. Hiring is great for consumers as it means they can afford to use professional-grade tools. It’s more profitable for retailers as they can make repeated revenue from hiring the same tools. It also has a lower environmental footprint, as it displaces the sales of cheaper tools. But, the reality is more complex. B&Q had tried direct hiring and it had been unsuccessful. There were various reasons for this, but essentially, the idea of hiring individual tools didn’t work for the DIY market - the additional complexity of hiring simply outweighed the potential benefits. For hiring to be successful, it needed to be much more beneficial to the consumer.

ProjectBox took the idea of selling outcomes (consumers want a hole in their wall, not a drill) and scaled it up to entire DIY tasks such as tiling, laying flooring and building decking.

If you want to tile a room, you hire a ProjectBox and get all the tools, materials and tailored instructions to complete the job. When you’re finished, the box is collected along with any project waste and unused materials.

Ultimately, we wanted to make hiring more desirable than buying. To do this, we needed to create a better DIY experience, making it easier and less risky for the consumer. We knew the biggest barriers to tackling DIY were a lack of experience and a lack of confidence, so the design process focused on how we could accelerate the learning curve and de-risk DIY.

To do this, we focused solely on tiling and immersed ourselves in the process. We organised tiling sessions to watch how people with no experience approached the problem - how they used the tools, what they were comfortable doing. Then we shadowed professional tilers to observe their techniques - how they achieved the perfect finish, what their shortcuts were and what tools they used.

We also spent a lot of time looking at existing instructions and how people use them. YouTube is now the go-to instructional resource, but the quality of the information varies and it rarely matches the tools people happen to have. Tablets and phones don’t mix well with tile adhesive either, so there is often a transcribing process.

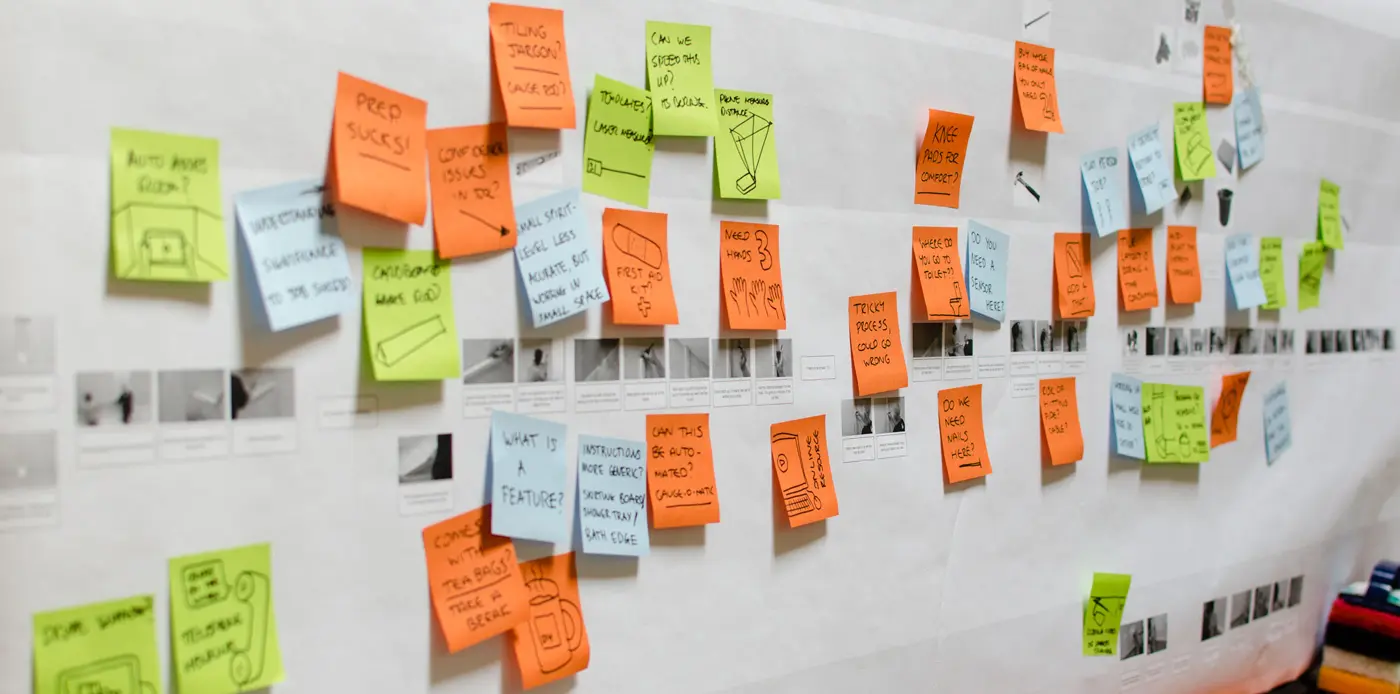

All this resulted in an in-depth user experience map for tiling, which identified problem areas, opportunities and design challenges. This allowed us to design the ordering process, the hardware and the instructions with an absolute focus on making the process of tiling as smooth as possible.

This project took an industry where price competition and material throughput rule the roost and created a service that made access and experience more desirable than owning products. This is very promising ground for the circular economy; great user experiences displacing linear sales models.